This 1973 TR6 popped up by chance. Someone pointed the ad in Kijiji and before we knew it it was in the shop. We bought it together with Jake, the shop's owner. Even though we do different thing for a living we both have the same passion for Triumphs and we couldn't miss the opportunity. So it is a common car and probably we will end up selling it when completed. For me it is more the fun of the restoration and the fact that one more Rusty Beauty will be back on the road.

I do not know too much of it's story though. I know only that the previous owner started the restoration due to a rotten frame. He sourced another, restored frame and assembled it with the suspension from the old one.

1973 Triumph TR6

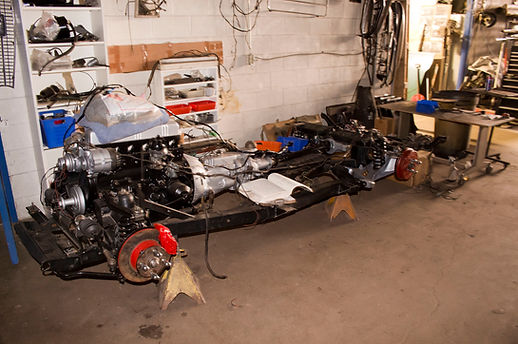

The body also needed work so he started working on that by basically stripping it out and then he stopped for one reason or another. When we bought the car it was in the condition you see it on this picture. The rest of it was in boxes. The valance was missing though - it was too rotten to keep according to the PO. The brake booster was also missing, but apart from that it was pretty complete.

As a starter we took the body off and started working on it. I say we, because the crew in the shop wasn't busy with official work so we took the opportunity to work on this car a little. So we patched the floor, the rear valance, we bought a front tub from another TR6, cut off the valance and installed it on our car, cleaned up the undercoating and started getting ready to assemble and paint it. We weren't planning on too deep restoration. It was just a put together project... Well, now I know it never works this way. We started taking steps backwards. Just one, then another, because we were finding more and more issues with the body and soon we were dealing with a sandblasted cheesy body. We couldn't decide what to do with the body as it turned out it needed a lot of work and at the time I wasn't really confident in my metalworking skills so we left it to the side and I moved to the frame. The chassis itself was very well restored and painted, but it looked like the PO just swapped the suspension without changing any bushings. So I took everything apart, cleaned up, de-rusted and painted the components, changed all the bushings and reassembled it. In the meantime the trimmers in the shop reupholstered the seats and door panels.

Next I decided to deal with the engine and transmission. Again my colleagues helped to clean and paint them, I rebuilt the carbs and it was time to start the engine and assess it's condition. At this point I also started filming the project and posting the videos in YouTube. So I ran some wires and hoses, played a little with the carbs and finally the engine started. It was running pretty well. No suspicious noises or ratlles, which was a good news, so I proceeded to measuring the compression. It was a little on the low side - around 150PSI. I tried a second test with a squirt of oil in each cylinder and that didn't change anything, which showed the piston rings were good, obviously the problem was in the valves. I took the head off, removed the valves and as expected at the back they were completely covered with carbon. So I cleaned them,

lapped them manually, assembled the head and leak tested the valves again. This time they were holding very well so I assembled the engine. While the head was off I took the opportunity to clean the carbon from the top of the pistons as well. Once I assembled it I measured the compression again and I was satisfied with the results. This time it was 170 - 175

At this point we hired someone, who was a mechanic and a bodyman, and a painter and many other things. He was hired for official shop projects, but he said he could fix our TR6 body in no time so we were more than happy to let him do it.

The next couple of months he was working a little bit at a time on the TR6, whenever he wasn't too busy with official work. And he was really fast. In one hour he would fix a rotten spot on the car - patch it, smoothen it with body filler and prime it right away "so it doesn't rust" as he said. We were so happy!

He was with us for 7-8 months and he managed to get the body ready for paint. He primed the whole car and then he painted the floor underneath, the wheel wells, the inside of the car and the engine bay, the inside of the fenders too - as they were separated from the car.

For the exterior he was going to rent a boot and paint it properly. So we decided to put the body on the frame, assemble the fenders, doors, hood and trunk lid and take it to paint in one piece. And that was where we started realizing that it was too good to be true. Somehow the fenders weren't fitting with the valances and sills, the doors and the hood were all over the place.... So at this point we realized that he never fit any panels together. He fixed everything as it was separated from the car even though the doors and the hood came from another car and he was expecting everything to fit.... As it turned out later his metalwork wasn't very good as well. We figured that most of the rotten areas he just covered with bondo without even patching them, which explained the speed. And since we weren't very happy with hiss other work on other projects as well we had to let him go and we were back to square one.

So the next winter I spent many nights and weekends redoing all the metalwork on that car, looking for more and more bodged areas and fixing them and finally in the spring all the metalwork was done and we started looking around for a paintshop to paint the car, but also to do all the prepping since I had done just roughly some smoothing with body filler here and there. Soon we found a shop and the owner came to look at the car. He confirmed he can do it and we sent the car with flat bed to his shop.

They kept the car for 5 or 6 weeks. Meanwhile they suggested to change the hood, because ours was very "distorted" in the middle and it would be very expensive to fix it. They had another one, so..... Of course I told them our hood was modified to fit, so the other hood probably wasn't going to fit and it would need to be modified as well. "Sure, no problem" they said and when the car came back I was shocked. The hood was totally misaligned, the gaps were horrible and the paint was a disaster. There were runs, orange peel, fish eyes.... What a disappointment! I had to realign, reshape, cut and weld the new hood to fit again and of course the whole entire paintwork needed to be redone, but the paintshop just refused to take the car back.

So it sat for a few months while we figured what to do and finally we decided to send it to another paint shop and re-do the entire paintwork. They kept the car for a very long time, but they did a good job. When it came back we were happy with it and finally I could start assembling it.

That was in the beginning of April, 2018.

I wrapped up my other project. the 1972 GT6 in the middle and started working on this one as it was first in the line :)

I started by assembling the engine bay. Installing the brake and clutch master cylinders, connecting brake lines, fuel lines. Then I installed the windshield wiper mechanism before I went too far and buried the openings under the dash. Then I ran the new harness and started installing all electrical components, dash, gauges... You know, there are so many things to install :)

By mid June the car was assembled just enough for a first start and test-drive. I had it on jack stands so we could "test-drive" it in the air first. The carburetors were rebuilt long time ago and not adjusted, but surprisingly she started and ran pretty well with them despite all the vacuum leaks I had to take care of. My main concern was the transmission and A-type overdrive as these were never tested before. We ran the engine a few times in the past, but never drove the car. So now I was really happy the transmission went into all gears and the Overdrive worked well (I jump-wired the solenoid).

I was so exited... I wanted to drive it now... It didn't take long to throw a seat inside and take it out for a backyard drive :) She ran so well. I was really happy! ...until she decided to spit oil in my face :) LOL, literally! The bonnet was not installed and there was no windshield frame as well, so when the line for the oil pressure gauge burst I got covered in oil along with the entire engine bay and the freshly painted panels :) At first I thought the engine was gone, but it was such a relief to find the only issue was the little plastic oil line. I ordered a steel braid one and replaced it and we had no issues ever since.

So I kept assembling it, installed sound deadening on the floor, new carpet, reupholstered in Tan leather seats and side panels, new dash pad and even new top! She looked amazing at the end.

So within 4 months just by spending few hours on her every once in a while I was able to complete her and used her as a daily driver for a while in order to test all systems and do all necessary adjustments. Till September I put more than 1000 miles on her and she was already running fantastic. On September 16th, 2018 she attended the British Car Day and that was the great finale of the almost 3 years long restoration.

There were many ups and downs. She had active periods followed by just hanging periods, many people had their hands on her, but I think she turned out amazing and now she is a proud member of the Completed Rusty Beauties

Gallery

|  |  |  |  |  |

|---|---|---|---|---|---|

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |  |  |  |

|  |  |